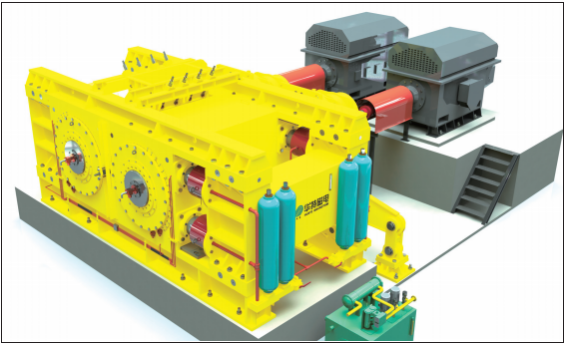

SINGLE DRIVE HIGH PRESURE GROUPING ROLL

Application Scope

Single-drive high pressure grinding roll yakanyatsogadzirirwa kugaya simende clinkers, the mineral dross, the steel clinkers uye zvichingodaro kuita madiki granules, kuti ultra-pwanya zvicherwa zvesimbi (iron ores, manganese ores, copper ores. , lead-zinc ores, vanadium ores nevamwe) uye kukuya zvicherwa zvisiri zvesimbi (marasha gangues,

feldspar, nephe-line, dolomite, limestone, quartz, zvichingodaro) kuita upfu .

Mamiriro & Kushanda Nheyo

◆ Dhiagiramu Yemisimboti Yekushanda

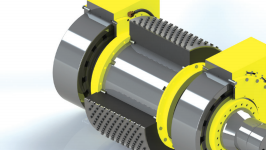

Iyo singledrive high pressure grinding roll inotora

Kukuya musimboti wezvinhu aggregate extrusion .

Imwe ndeye stationary roll uye imwe inofambiswa roll.

Mipumburu miviri iyi inotenderera zvakapesana nekumhanya kwakafanana .

Zvishandiso zvinopinda kubva pakuvhurwa kwekudya kwepamusoro,

uye inogayiwa nekuda kweextrusion nekudzvinyirirwa kwepamusoro mugomba remapumburu maviri, uye inoburitswa kubva pasi.

◆Dira chikamu

Chete mota drive inodiwa,

iro simba rinofambiswa kubva kune yakamira roll kuenda kune inofambiswa roll kuburikidza negiya system,

kuitira kuti mipumburu miviri inyatso wiriraniswa pasina kutsvedza.

Basa racho rose rinoshandiswa kune zvinhu extrusion,

uye chiyero chekushandiswa kwesimba chakakwira, chinochengetedza 45% yemagetsi zvichienzaniswa neyakajairwa high pressure grinding roll.

◆ Kumanikidza kushandisa system

Iyo yakasanganiswa chitubu mechanicha yekumanikidza kushandisa system inoita kuti inofambiswa roll irege kuchinjika.

Kana pane simbi yekunze inopinda.

iyo chitubu dhizaini yekushandisa system inodzokera kumashure uye inogadzirisa nenguva, kuve nechokwadi chekuti chiyero chekushanda chakakwira se95%;

nepo iyo yechinyakare yakakwira dzvinyiriro yekukuya roll inoita kuti udzivise, iyo hydraulic oiri inoda kuburitswa kuburikidza nepombi kuti isunungurwe.

Chiito chacho chinononoka, chinogona kukonzera kukuvadza kune roll roll kana kusashanda kweiyo hydraulic system.

◆Kukungurutsa pamusoro

Iyo roll pamusoro iri pakatarisana neyakaiswa welded ine alloy kupfeka-resistant welding material, uye kuoma kunogona kusvika HRC58-65; kudzvanywa kunogadziriswa otomatiki nezvinhu,

iyo isingaite chete chinangwa chekukuya, asiwo inodzivirira roll pamusoro;

iyo inofambiswa roll uye yakamira roll inoshanda zvakafanana pasina kutsvedza kukweshera.

Nokudaro, hupenyu hwebasa remupumburu hwakanyanya kudarika iyo yakajairwa high pressure grinding roll .

Main Technical Features

◆ Kubudirira Kwekushanda Kwepamusoro. Kuenzaniswa neyechinyakare yekupwanya michina, iyo yekugadzirisa huwandu inowedzera ne40 - 50%.

Iko kugadzirisa kwePGM1040 kunogona kusvika kumativi makumi mashanu - 100 t / h, iine simba re90kw chete.

◆ Low Energy Consumption . Sezvinei neimwe roll yekutyaira nzira, inoda mota imwe chete kutyaira.

Iko kushandiswa kwesimba kwakaderera zvikuru. Kuenzaniswa neyechinyakare kaviri drive HPGR, inogona kuderedza kushandiswa kwesimba ne20 ~ 30%.

◆ Good Wear-resistant Quality . Nekungotyaira mota imwe chete, kuwiriranisa kuita kwemaromburu maviri kwakanaka kwazvo.

Nekupfeka-resistant welding nzvimbo, ma rolls ane yakanaka kupfeka-resistant mhando uye anogona kuchengetedzwa zviri nyore.

◆ High Operation Rate: ≥ 95%. Nekugadzirwa kwesainzi, midziyo inogona kumanikidzwa neiyo yakakwira pressure spring group.

Iyo yekumanikidza yekushanda inogona kugadziridzwa otomatiki sekuenderana kwechitubu boka compress. Iko hakuna malfunction point .

◆ High Automation uye nyore kugadzirisa. Pasina iyo hydraulic system, kune yakaderera kusashanda mwero

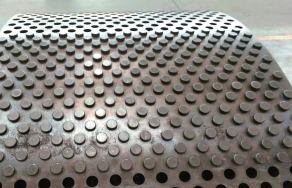

◆ The roll surface is overfacing welded with alloy wear-resistant welding material, nehupamhi hwekuoma uye yakanaka kupfeka-resistant;

Kudzvanywa kwechitubu kunobva kune simba rekuita rezvinhu, uye kumanikidza kunogara kuri pakati,

izvo zvisingaite chete chinangwa chekupwanya,

asiwo inodzivirira roll pamusoro; iyo inofambiswa roll uye yakamira roll inosungirirwa uye inofambiswa negiya system,

uye kumhanya kwakanyatso kuwiriraniswa, nekudaro kudzivirira kutsvedza kukweshera pakati pechinhu uye roll pamusoro.

Naizvozvo, hupenyu hwesevhisi hwakanyanya kukwirira kupfuura iyo yeaviri drive HPGR .

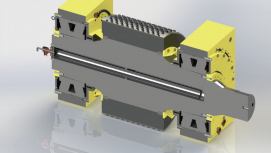

◆ Chimiro chakasimba uye nzvimbo duku yepasi.

Technical Parameters

| Model | Roll dhayamitamm | Rollwidthmm | M ax .feedsize(Simende, simbi slag, oreslag) mm | Optimum feedsaizi(simbim i r a l ,isiri-simbimineral) mm | mmOutput size(simende)mm | ProcessingcapacityT/h | M o rsimba Kw | Rondedzera zviyero(L×W×H)mm |

| PGM0850 | φ800 | 500 | 50 | 30 | Kuronga,<4 | 30~40 | 37 | 2760×2465×1362 |

| PGM1040 | φ1000 | 400 | 50 | 30 | Kuronga,<4 | 50~80 | 90 | 4685×4300×2020 |

| PGM1060 | φ1000 | 600 | 50 | 30 | Kuronga,<4 | 70~110 | 110 | 4685×4300×2020 |

| PGM1065 | φ1000 | 650 | 50 | 30 | kunyaradza,<4 | 100~160 | 200 | 5560×4500×2200 |

| PGM1250 | φ1200 | 500 | 50 | 30 | Kuronga,<4 | 120~180 | 250 | 6485×4700×2485 |

| PGM1465 | φ1400 | 650 | 50 | 30 | Kuronga,<4 | 240~320 | 630 | 9200×6320×3600 |

| PGM1610 | φ1600 | 1000 | 50 | 30 | Kuronga,<4 | 500~650 | 1250 | 10800×8100×4400 |

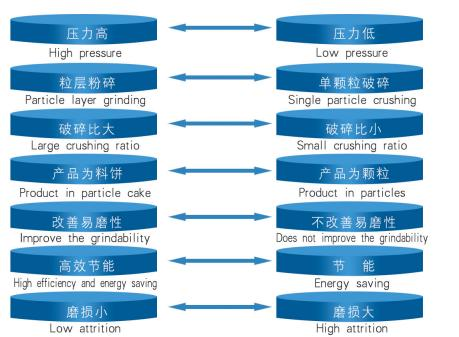

KUFANANA PAKATI PAIMWE DHAVHIDHI HPGR NECONVENTIONAL HPGR

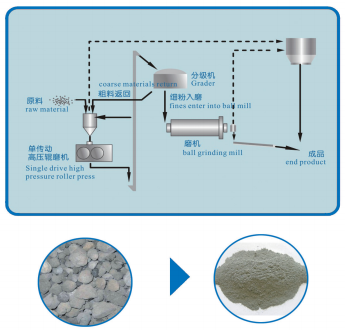

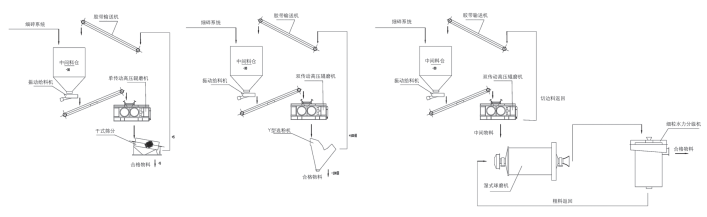

KUTANGA KUGAYA PROCESS FLOW CHART YE SINGLE DRIVE HPGR

Pre-kugaya simende, ore slag uye simbi slag "Kuwedzera kupwanya uye kushoma kugaya, kutsiva kugaya nekupwanya", ndiko kuti, kufanogaya, yave tekinoroji yakakura yekugadzira pombi chigayo kuwedzera kugadzirwa uye kuderedza kushandiswa kwesimba. . Sechishandiso chepamusoro-soro chisati chagayiwa chekuchengetedza simba, HPGR imwe chete inogona kupwanya zvinhu kusvika -4mm kana -0 .5mm, iyo 0 .08mm inodarika 30%. Kugona kwechigayo chebhora chinoshandiswa kunogona kuwedzerwa ne50 ~ 100%, uye iyo system yekukuya mashandisiro emagetsi inogona kuderedzwa ne15 ~ 30%.

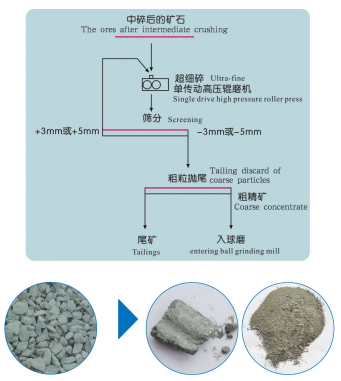

ULTRA FINE CRUSHING PROCESS FLOW Chati YEMETALLIC MINERAL NEIMWE CHETE DRIVE HPGR

Ultra Yakanaka Kupwanya kweMetallic Mineral

Kana maminerari achipfuura nemugero pakati pemapumburu maviri, anopwanyika kuita zvidimbu zvakanaka zve -5 mm kana -3 mm uye huwandu hukuru hwehupfu nechisimba chakanyanya. Pamusana pesimba risina simba rekubatana kwekubatana pakati peiyo inobatsira mineral uye gangue, kuneta kuputsika kana micro-crack uye kushushikana kwemukati kunogadzirwa nyore nyore. Chikamu cheiyo interface chichave chakaparadzaniswa zvachose.

Nekuda kwehuwandu hwehupfu hwakatsetseka hwakaburitswa kubva kuHPGR uye chokwadi chekuti zvicherwa zvakapwanyika padivi penzvimbo yekuparadzanisa, zvichienzaniswa nekupwanya kwakajairwa, chikamu chekukura muzvigadzirwa zvakapwanyika chinodzikiswa, uye miswe inorasa ef- chimiro chakanaka.

Zvose giredhi yakakora uye goho rekurasa marara zvinovandudzwa zvikuru.

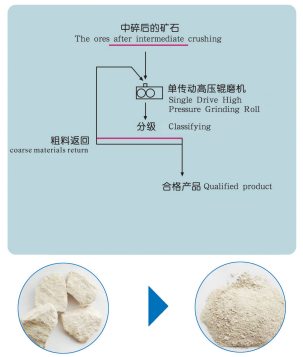

APPLICATION PROCESS FLOW Chati YEISI-METALLIC MINERAL NEIMWE DRIVE HPGR

Kwete-Metallic Mineral Kukuya

Zvichienzaniswa nemidziyo yekukuya yechinyakare, single-drive HPGR ine mabhenefiti emuchina ma- machine mahombe, kushandiswa kwesimba kushoma, kushomeka uye kusvibiswa kwesimbi kushoma; iyo chigadzirwa kunaka kunogona kudzorwa kubva pa20 mesh kusvika 120 mesh, iyo inogona kutsiva bhora chigayo uye kugadzira nzira nyowani yekukuya.

HPGM SERIES YAKAKURA PRESSURE KUGAYA ROLL

Kushanda Nheyo

HPGM yakatevedzana yakakwira dhizaini yekukuya roll imhando nyowani yemagetsi-yekugayira michina yakagadzirwa nemusimboti wepamusoro-kumanikidza zvinhu layer pulverization. Inoumbwa netumwe tuviri twekusvina tunotenderera nekamwe panguva yakaderera. Imwe ndeye yakamira mupumburu uye imwe iri roll inofambiswa, ayo ose anofambiswa nemota ine simba guru. Zvishandiso zvinodyiswa zvakaenzana kubva pamusoro pemapumburu maviri, uye zvinoramba zvichitakurwa mugomba remapumburu nemupumburu wekusvina. Mushure mekuiswa pasi pekumanikidzwa kwakanyanya kwe50-300 MPa, iyo dense zvinhu keke inoburitswa pamushini. Mune keke rakaburitswa, mukuwedzera kune chimwe chikamu chezvigadzirwa zvakakwaniriswa, chimiro chemukati chezvikamu zvezvisina kukodzera zvigadzirwa zvinozadzwa nenhamba yakawanda yemadiki madiki nekuda kweiyo yakanyanya kudzvanywa extrusion, kuitira kuti kugaya kwechinyorwa kuve. kuvandudzwa zvikuru . Pamusoro pezvigadzirwa mushure me extrusion, mushure mekuputsika, kurongedza uye kuongorora, zvinhu zvakanaka zvisingasviki 0.8 mm zvinogona kusvika anenge 30%, uye zvinhu zvisingasviki 5 mm zvinogona kusvika kupfuura 80%. Nokudaro, mukuenderera mberi kwekugaya, kushandiswa kwesimba kunogona kuderedzwa kusvika pamwero mukuru, kuitira kuti simba rekugadzira yezvigayo zvigone kushandiswa zvakakwana, kazhinji bhora rekugadzira bhora rinogona kuwedzerwa ne 20% ~ 50. %, uye simba rose rekushandisa rinogona kuderedzwa ne30% ~ 50% kana kupfuura.

Minda Yekushandisa

Kune akawanda marudzi ezviwanikwa zvesimbi muChina, asi hunhu hwemhando zhinji dzemaminerari hurombo, hwakasiyana-siyana uye hwakanaka. Kuti vagadzirise matambudziko akamira muhupfumi, tekinoroji uye kuchengetedzwa kwezvakatipoteredza kwekusimudzira migodhi, mabhizinesi emigodhi emigodhi edzimba anosuma, kugaya uye kutora michina yekugadzira migodhi yekunze uye inoshanda. Mune iyi musika kumashure, iyo HPGR ndeyepamusoro-inoshanda yekukuya michina yakatanga kutsvagirwa uye kuratidzwa, uye inotanga kushandiswa mumabhizinesi emigodhi yesimbi. Ndiyo zvakare michina yekugadzira migodhi inonyanya kutariswa neindasitiri yezvicherwa zvemumba. Zvinogona kutaurwa kuti HPGR inoshandiswa zvakanyanya mumigodhi yesimbi yemumba . Iyo HPGR yakashandiswa zvakanyanya kumba nekune dzimwe nyika mukukuya muindasitiri yesimende, granulation muindasitiri yemakemikari, uye kugaya zvakanaka pellet kuti iwedzere nzvimbo chaiyo. Inoshandiswa pakupwanya kwesimbi ore kuita zvinangwa zvakasiyana sekurerutsa nzira yekupwanya, kuwedzera kupwanya uye kushoma kugaya, kuvandudza kugadzirwa kwehurongwa, kugadzirisa kugaya kana zviratidzo zvekuparadzanisa.

Inoshanda Kushandisa Scope

1. Kukuya kwepakati, kwakanaka uye ultrafine yezvinhu zvakawanda .

2. Mukugadzirwa kwemaminerari, inogona kuiswa pamberi pechigayo chebhora, sechigadziro chekugadzika, kana kugadzira chigadziro chakasanganiswa nebhokisi rebhora .

3. Muindasitiri ye oxidized pellet, inogona kutsiva chigayo chinowanzo shandiswa nyoro.

4.Muzvivakwa zvekuvaka, refractory zvinhu uye mamwe maindasitiri, zvakabudirira kushandiswa mu simenti clinker, limestone, bauxite uye kumwe kukuya.

Product Advantages

1. Kugara kudzvinyirira dhizaini kunovimbisa kutsvedza kudzvanywa pakati pemapumburu uye inova nechokwadi chekupwanya mhedzisiro.

2. Kururamisa otomatiki kutsauka, kunogona kukurumidza kugadzirisa gaka repumburu kuti ive nechokwadi chekutsetseka kwemidziyo.

3. Mupendero wekuparadzanisa system inoderedza mhedzisiro yemhedzisiro pamhedzisiro yekupwanya.

4. Nemasimende e carbide studs, hupenyu hurefu hwebasa, kugadzirisa kuri nyore, uye kunotsiviwa.

5. Bhangi revhavha rinotora zvinhu zvinotengeswa kunze kwenyika, uye hydraulic system ine dhizaini inonzwisisika uye kuvimbika kwakanaka.

Chimiro cheHPGR

| Model | Roll dhayamitamm | Roll yakafara mm | throughputkukwanisa | Saizi yekudya | Machine uremut | Simba rakaiswa |

| HPGM0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 |

| HPGM0850 | 800 | 500 | 50-110 | 20-35 | 25 | 150-220 |

| HPGM1050 | 1000 | 500 | 90-200 | 20-35 | 52 | 260-400 |

| HPGM1250 | 1200 | 500 | 170-300 | 20-35 | 75 | 500-640 |

| HPGM1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 |

| HPGM1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 |

| HPGM1480 | 1400 | 800 | 270-630 | 30-40 | 172 | 800-1260 |

| HPGM16100 | 1600 | 1000 | 470-1000 | 30-50 | 220 | 1400-2000 |

| HPGM16120 | 1600 | 1200 | 570-1120 | 30-50 | 230 | 1600-2240 |

| HPGM16140 | 1600 | 1400 | 700-1250 | 30-50 | 240 | 2000-2500 |

| HPGM18100 | 1800 | 1000 | 540-1120 | 30-60 | 225 | 1600-2240 |

| HPGM18160 | 1800 | 1600 | 840-1600 | 30-60 | 320 | 2500-3200 |

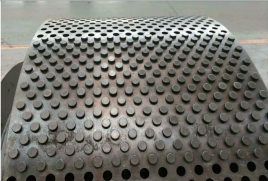

New type stud roll surface tekinoroji

Inotora yakakwirira-mhando yakaoma alloy studs ine kuomarara kwakanyanya uye yakanaka kupfeka kuramba.

Iyo stud kurongeka kwakagadzirwa nekombuta simulation,

uye kurongeka kwacho kunonzwisisika, kunogona kuumba yunifomu yezvinhu layer pakati pezvidzitiro, zvichinyatso chengetedza zvitubu uye roll pamusoro,

uye kuvandudza hupenyu hwesevhisi hwekusvina roll. Iwo matudhi akaiswa ane adhesive akakosha anotengeswa kunze kwenyika kuitira nyore kutsiva.

Kuparadzanisa tekinoroji ye roll bush-ing uye main shaft

Muviri mukuru wekusvina mupumburu wakagadzirwa nemhando yepamusoro yesimbi yakagadzirwa, uye roll bushing inogadzirwa nepamusoro-soro alloy steel . Iyo huru shaft uye mipumburu inogadzirwa nezvinhu zvakasiyana-siyana, izvo zvinovandudza kuoma kweiyo shaft huru uye kuomarara kwe roll bushing . Hupenyu hwebasa reshaft bushing hunovandudzwa zvakanyanya. Kutsiviwa kwema roll bushing kuri nyore .

Kutakura kukurumidza kukwira uye kudzika tekinoroji Yepamusoro-soro tapered gomba mabhengi anogamuchirwa uye yakakwirira-kumanikidza mafuta tank inogadzirwa. Kutakura kunogona kuderedzwa nyore nyore kuburikidza ne-high-pressure mafuta pombi, zvakanyanya kuderedza kuoma kwekutsiva kubereka uye kugadzirisa kugadzirisa kushanda.

Multiple yakasanganiswa yekuisa chisimbiso tekinoroji

Chisimbiso chinotakura chinotora zvakasiyana-siyana zveJ-mhando plus V-mhando uye labyrinth zvisimbiso, uye yakasanganiswa yekuisa chisimbiso tekinoroji inogonesa kuvharisa mhedzisiro yekubereka.

Iron Ore Beneficiation Flow

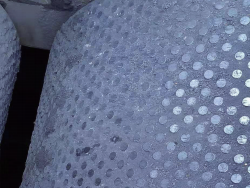

Yepamusoro Kupfeka-Inodzivirira Roll Surface ine maStuds

Mushure mokunge zvinhu zvawedzerwa,

dense material layer inoumbwa pamupumburu wepamusoro kudzivirira iyo roll surface.

Raw Material

Material Cake