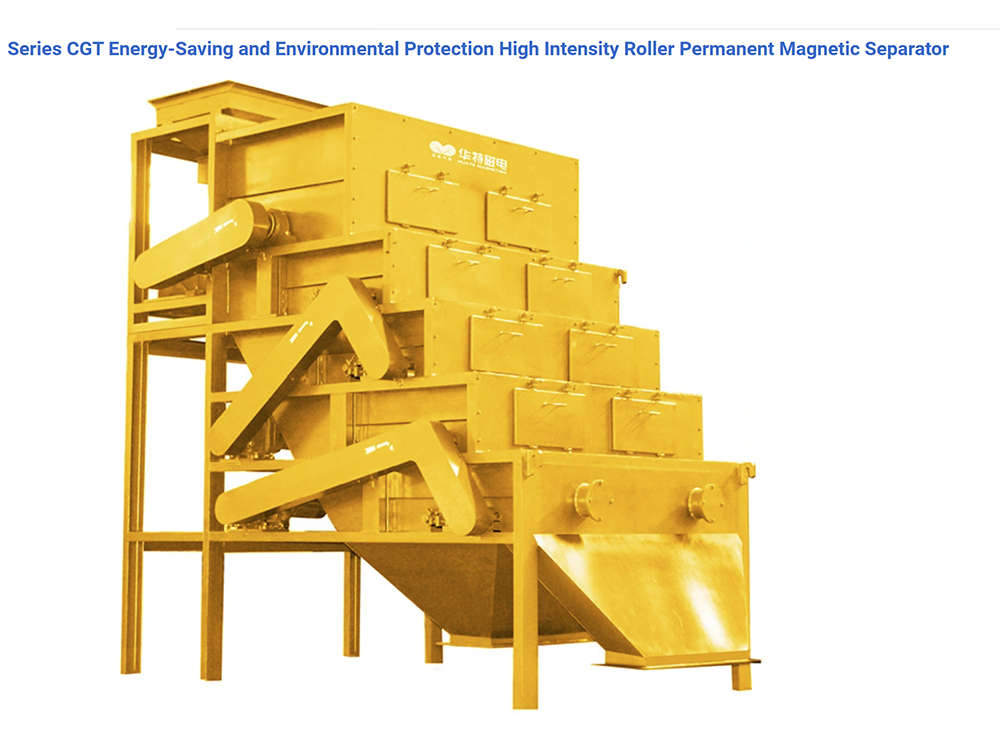

CGT High Field Simba Drum Permanent Magnetic Separator

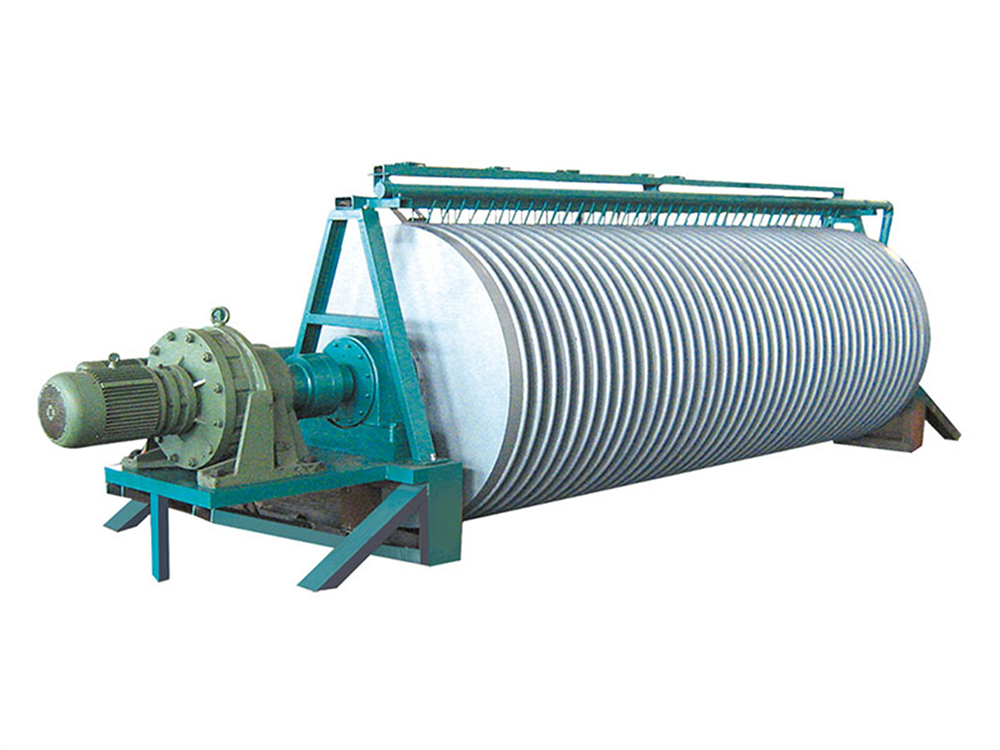

Application

Kubvisa tsvina ine simba remagineti kubva kune granular kana coarse poda zvinhu.Inogona kushandiswa kucheneswa kweasiri-simbi zvicherwa senge ceramics, girazi, refractory zvinhu, pamwe nekucheneswa kwemakemikari, chikafu, uye maindasitiri emishonga. Inogona zvakare kushandiswa kune yakaoma pre-kusarudzwa kweasina simba magineti emaminerari akadai sehematite uye limonite, pamwe nekuomeswa kuparadzaniswa kwemanganese ore.

Technical Characteristics

◆ Iko kunzwisisika kusanganiswa kwechigarire magineti chigubhu uye chigarire magineti chigubhu chinogona kuita zviri nani kubviswa kwesimbi.

◆ Iyo ngoma inotora rudzi rutsva rwekubhadhara magnetic pole magnetic system, iyo ine simba guru remagineti uye kusveta kwakasimba.

◆ Magnetic system yedhiramu inogona kuitwa mumhando inoputika, inovandudza zvikuru chiyero chekuchenesa.

◆ Nzvimbo yepamusoro yemagineti yedhiramu inogona kusvika ku8000Gs.

◆ The rotary speed of the drum and magnetic roller inogadziriswa kuburikidza nekushandurwa kwefrequency kuti isangane nehupamhi hukuru hukuru uye zvinodiwa zvekugadzira.

◆ Magnetic roller anotora a concentrated magnetic composite magnetic system, ane magnetic field simba re 18000Gs uye yakakwirira gradient.

◆ Bhandi rekutakura rinoshandiswa kune magnetic roller rakagadzirwa nezvinhu zvakakosha uye rine zvakanaka kupfeka kusagadzikana.

◆ Iyo inodzoreka yekudyisa sisitimu inovimbisa kuenzana kwezvinhu painoyerera kuburikidza neiyo magnetic field area.

◆ Weak magnetic oxides inogona kucheneswa otomatiki, kuve nechokwadi chekushanda kwenguva refu uye isina matambudziko.

◆ Reserved guruva rekubvisa chiteshi chepakati guruva rinobuda, kusangana nekuchengetedzwa kwezvakatipoteredza zvinodiwa.

Main Technical Parameters

| Model | Diameter × Kureba mm×mm | Rotary speed r/min | Magnetic induction kusimba Gs | Nhamba yemag | Kukora kwebhandi mm | Processing kukwanisa t/h | Motokari powerkW | ||||

| Drum | Magnetic roller | Drum | Magnetic roller | Drum | Magnetic roller | Drum | Magnetic roller | ||||

| CGT-3/5 | Φ300x500 | Φ100x500 | 30 | Variable frequency inochinjika 17-82 | ≥4000 | ≥12000 | 1 | 0.1-2.0 | 0.8-1.0 | 0.75 | 0.37 |

| 2CGT-3/5 | 2 | 0.37 | |||||||||

| 3CGT-3/5 | 3 | 0.55 | |||||||||

| 4CGT-3/5 | 4 | 0.55x2 | |||||||||

| CGT-4/8 | Φ400x800 | Φ100x800 | 1 | 1.2-2.0 | 1.1 | 0.55 | |||||

| 2CGT-4/8 | 2 | 0.75 | |||||||||

| 3CGT-4/8 | 3 | 0.75 | |||||||||

| 4CGT-4/8 | 4 | 0.75x2 | |||||||||

| CGT-5/10 | Φ500x1000 | Φ100x1000 | 1 | 2.0-3.5 | 1.5 | 0.55 | |||||

| 2CGT-5/10 | 2 | 0.75 | |||||||||

| 3CGT-5/10 | 3 | 0.75 | |||||||||

| 4CGT-5/10 | 4 | 0.75x2 | |||||||||

| CGT-5/12 | Φ500x1200 | Φ100x1200 | 1 | 4.0-7.0 | 2.2 | 0.75 | |||||

| 2CGT-5/12 | 2 | 1.1 | |||||||||

| 3CGT-5/12 | 3 | 1.1 | |||||||||

| 4CGT-5/12 | 4 | 1.10x2 | |||||||||

| CGT-6/15 | Φ600x1500 | Φ100x1500 | 1 | 7.0-10.0 | 4 | 0.75 | |||||

| 2CGT-6/15 | 2 | 1.5 | |||||||||

| 3CGT-6/15 | 3 | 1.5 | |||||||||

| 4CGT-6/15 | 4 | 1.50x2 | |||||||||